Some other printers that have been used for to build the parts are : One of the team’s Prusa printers has done 30 days worth of printing in a 3 month period with no issues whatsoever. These are known to produce good consistent results and highly rated albeit they are expensive (approx $750 USD in kit form + shipping). Everyone loves seeing 3D printers in action.Ī number of the project team have Prusa i3 printers through their paces.

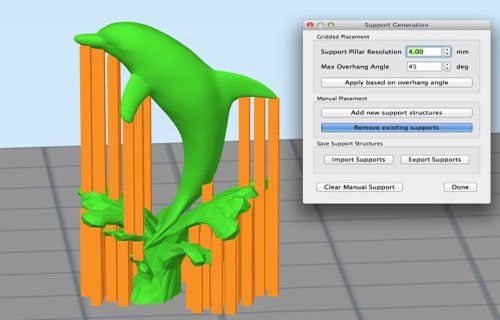

Involve your family printing things for them.Build other things when you want (button boxes, steering wheel components).Any replacement parts in the unlikely event an original fails you can re-print.Owning a 3D printer you get these advantages: You will need to make a “buy vs outsource” decision. Some builders are lucky and have access to printing services cheap (friends) through to commercial quotes upto $900EUR to $1600AUD. Please note there is a dedicated thread on the German forum for 3D Printing parts, and a lot of help in the RaceDepartment threadĬloseup showing the extruded lines generated by Slicing software gcode files on an SD card, and into your printer Run them through a “Slicing” program, this (a) turns the solid 3D model into a structure of layers and ‘infill’, then (b) outputs the “GCode” this is commands that tell the printer what to do, layer by layer,.The SFX-100 actuators require around 200 hours of printing with 20 individual parts that need printing. Once you get past the initial setup it’s usually only a couple of minutes setup work and your print is underway. It isn’t as daunting as you think, and isn’t as expensive as you’d think. Without 3D printing this would likely mean CNC machined aluminium blocks.

3D printing makes the actuators possible – the bearings, and motor all need to be at certain positions and held solidly in alignment.

0 kommentar(er)

0 kommentar(er)